The first thing when making a knife is coming up with a design. I have been trying to think of something to do with the ATS-34 and kydex I have had in storage for quite a while and have been admiring some of the nice small neck knives and tools made by Peter Atwood http://www.atwoodknives.com. I thought making something similar would be a really good way to do some stock removal knives, they are also small enough that I think I can get a few done for the Canberra Knife Show coming up in a month. These knives are now for sale at the Available Knives page.

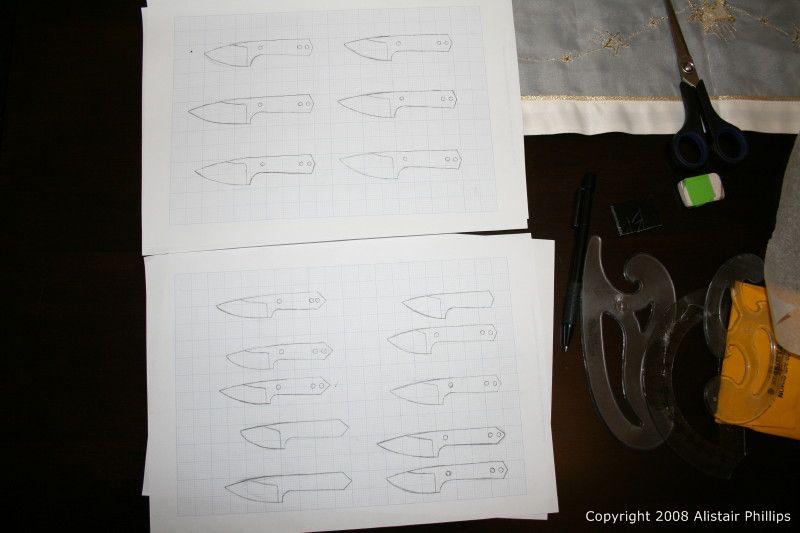

The first picture shows just how many designs I went through to get something I felt was small enough, had the right handle to blade proportions. The designs on the top page I decided were all to big and I wanted something smaller. I was trying to restrain the designs to within a box no longer than 3 inches the reason being I wanted to be able to get 2 knives out of one bit of 3 x 1 1/2 inch piece of steel. It wasn't until I stopped trying to draw the knife within a box and I setup a few pictures with the middle of the tang as the starting point that I reached my ideal design. You can see a tick next to the final design. It was a little longer the 3 inches overall but I wanted a pointer tip so I was happy to compromise. After going through all those designs I think I will be doing some more sketchy drawing of my knives to get an overall idea before I start to refine the design on the graph paper.

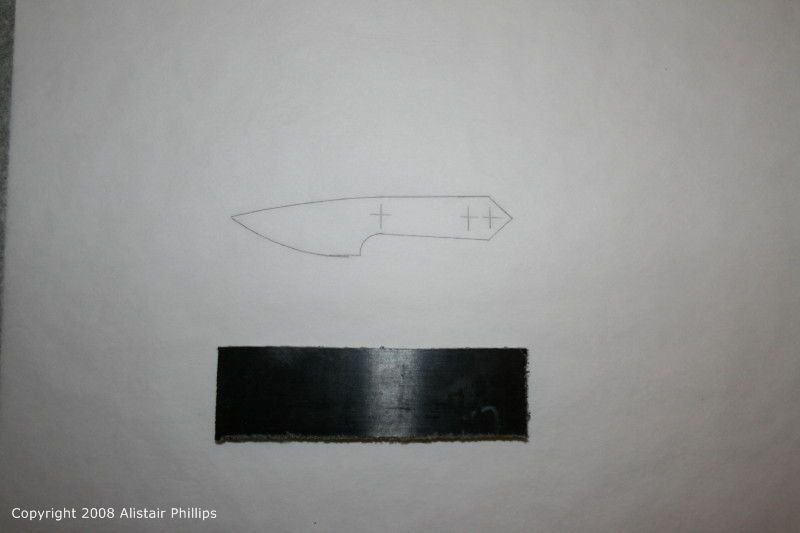

Next was to make a copy of the pattern onto some tracing paper, I used a set of french curves to create very even curves for the final template. You can also see the piece of micarta I will be using to make the template. If I was only making one knife from this design I wouldn't bother to make a template but since I am going to make four of them it will be easier with one. Also if the knives prove popular at the knife show I will be able to make some more.

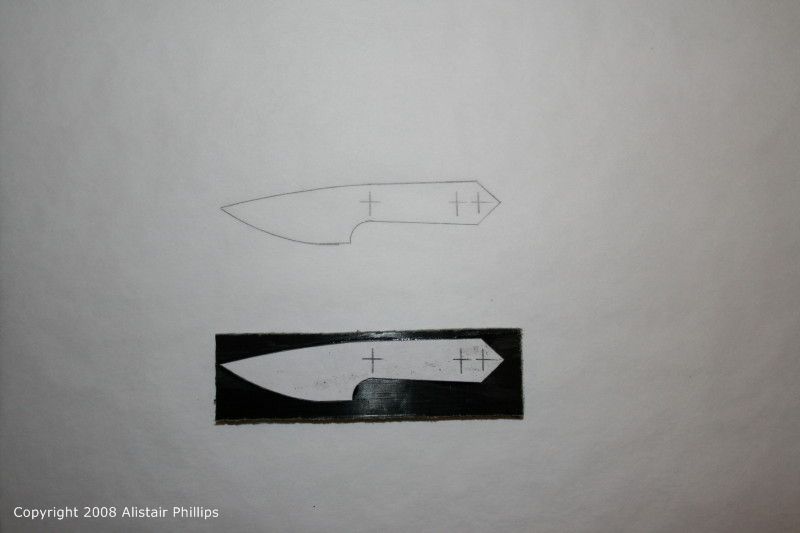

I photocopied the template, cut it out and glued it to the micarta with some pva glue.

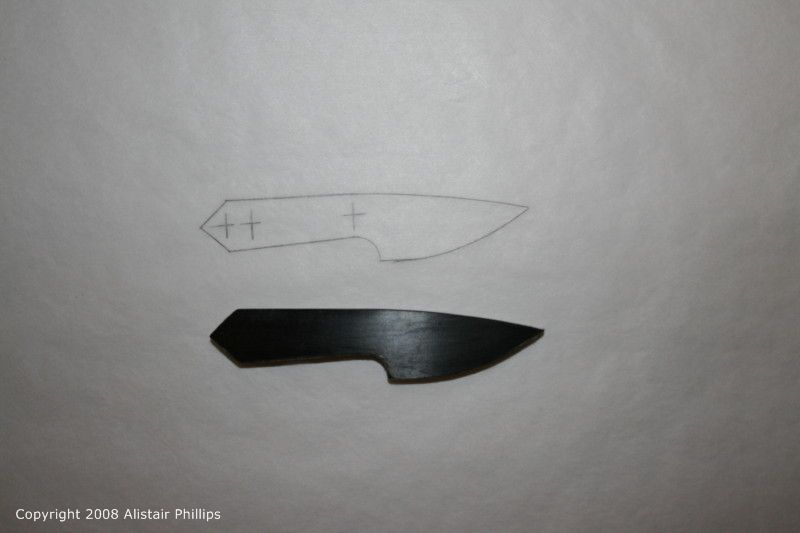

Here is the final template I have made. It was profiled out on the grinder, I had to use a round file on the inside curve since it it was too sharp for the grinder to get to. Useful to know for when I will be profiling the steel blades. I won't be putting the locations to drill the holes in the template as each knife that I profile will be slightly different and I will be determining where to drill then holes then.